Features & Benefits

- Raise or stabilize PH

- Solid acrylic construction

- High Torque-low RPM motor *

- Quick connect fittings

A Reactor built for Professionals, by Professionals.”

Model No.: KS-100, KS-150, KS-250

Reef Octopus Kalk Stirrer (Nilsen Reactor) carries a high torque low RPM motor that effectively, silently and gently mixes your calcium hydroxide (Kalkwasser). This method is not only ideal but is also the safest way of dosing the freshest possible Kalkwasser to your reef system. The Reef Octopus Kalk Stirrer is designed to keep the undissolved particles at the bottom of the reactor chamber while always leaving the clear highly saturated Kalkwasser liquid at the top. Adding Kalk powder couldn’t be easier with just a few twists of the large thumb screws releasing the seal-tight lid for quick and easy Kalk refills.

No need for powerheads that randomly need to be cleaned or replace and no more risky dosing with large vats of lime water which take up valuable space. You will never have to worry about premixing or clogs again when using our new innovative and efficient Kalk Stirrer (Nilsen Reactor) which are extremely easy to use and salt-water safe, making them simply the most economical and best Kalk reactor out there.

*The Kalk Stirrer uses a motor that has a lifetime of about 1500 hours. Please don’t run unit continuously.

| Article Code | Items | KS-100 | Article Code | Items | KS-150 | Article Code | Items | KS-250 | |||

| Model NO. | Qty | Model No. | Qty | Model No. | Qty | ||||||

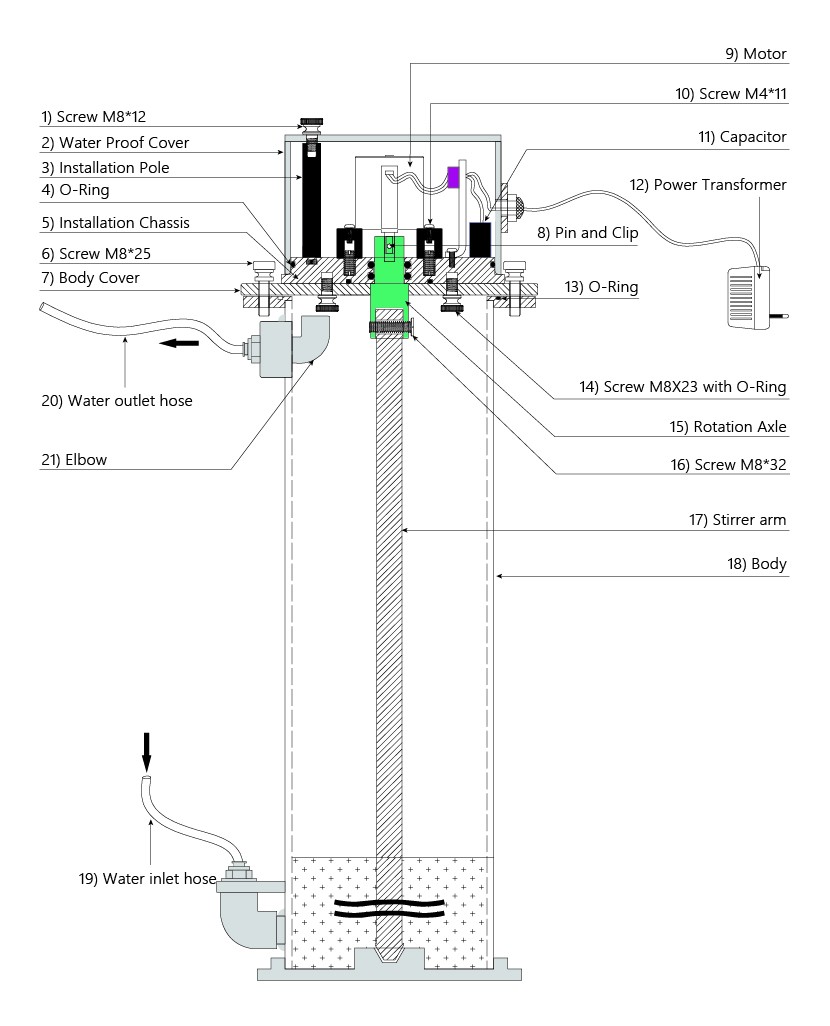

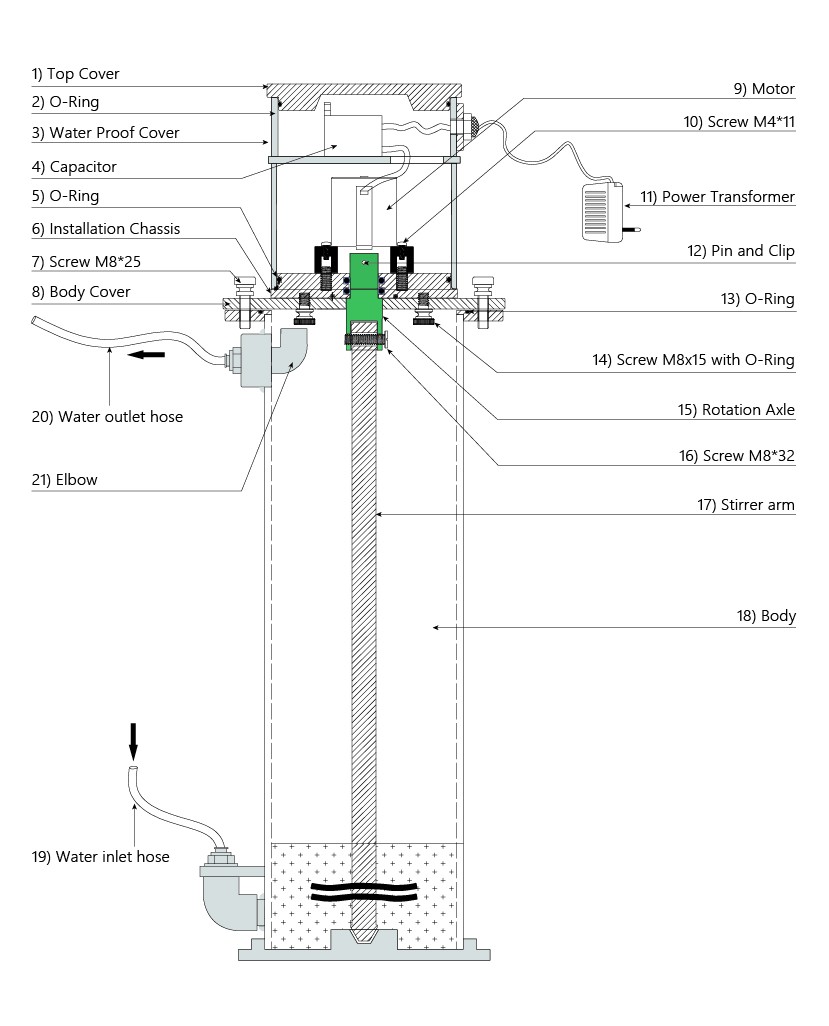

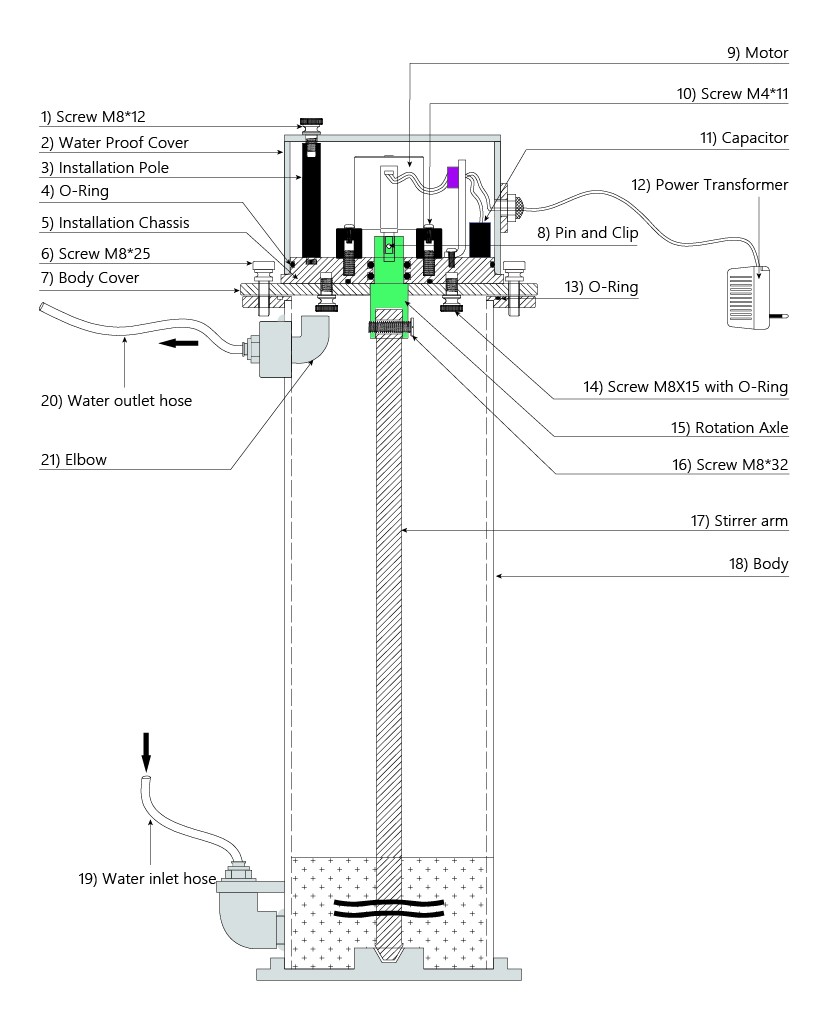

| 1 | Top Cover | – | 1 | 1 | Screw M8*12 | – | 1 | 1 | Screw M8*12 | – | 1 |

| 2 | O Ring | – | 1 | 2 | Water Proof Cover | – | 1 | 2 | Water Proof Cover | – | 1 |

| 3 | Water Proof cover | – | 1 | 3 | Installation Pole | – | 1 | 3 | Installation Pole | – | 1 |

| 4 | Capacitor | – | 1 | 4 | O Ring | – | 1 | 4 | O Ring | – | 1 |

| 5 | O Ring | – | 1 | 5 | Installation chassis | – | 1 | 5 | Installation chassis | – | 1 |

| 6 | Installation chassis | – | 1 | 6 | Screw M8*25 | – | 6 | 6 | Screw M8*25 | – | 12 |

| 7 | Screw M8*25 | – | 6 | 7 | Body Cover | – | 1 | 7 | Body Cover | – | 1 |

| 8 | Body Cover | – | 1 | 8 | Pin & Clip | – | 1 | 8 | Pin & Clip | – | 1 |

| 9 | Motor | – | 1 | 9 | Motor | – | 1 | 9 | Motor | – | 1 |

| 10 | Screw M4*11 | – | 4 | 10 | Screw M4*11 | – | 5 | 10 | Screw M4*11 | – | 5 |

| 11 | Power Transformer | – | 1 | 11 | Capacitor | – | 1 | 11 | Capacitor | – | 1 |

| 12 | Pin & Clip | – | 1 | 12 | Power Transformer | – | 1 | 12 | Power Transformer | – | 1 |

| 13 | O Ring | – | 1 | 13 | O Ring | – | 1 | 13 | O Ring | – | 1 |

| 14 | Screw M8*15 with O-Ring | – | 3 | 14 | Screw M8*15 with O-Ring | – | 3 | 14 | Screw M8*23 with O-Ring | – | 3 |

| 15 | Rotation Axle | – | 1 | 15 | Rotation Axle | – | 1 | 15 | Rotation Axle | – | 1 |

| 16 | Screw M8*32 | – | 1 | 16 | Screw M8*32 | – | 1 | 16 | Screw M8*32 | – | 1 |

| 17 | Stirrer arm | – | 1 | 17 | Stirrer arm | – | 1 | 17 | Stirrer arm | – | 1 |

| 18 | Body | – | 1 | 18 | Body | – | 1 | 18 | Body | – | 1 |

| 19 | Water inlet hose | – | 1 | 19 | Water inlet hose | – | 1 | 19 | Water inlet hose | – | 1 |

| 20 | Water outlet hose | – | 1 | 20 | Water outlet hose | – | 1 | 20 | Water outlet hose | – | 1 |

| 21 | Elbow | – | 1 | 21 | Elbow | – | 1 | 21 | Elbow | – | 1 |

| Product | Wet/Dry | Diameter | Footprint | Height | Quick Connect Input and Output | ||||||

| mm | inch | mm | inch | mm | inch | mm | inch | ||||

| KS-100 | Dry | 100 | 3.9 | 140 | 140 | 5.5 | 5.5 | 700 | 27.6 | 6.30 | 1/4 |

| KS-150 | Dry | 150 | 5.9 | 195 | 195 | 7.7 | 7.7 | 660 | 26.0 | 6.30 | 1/4 |

| KS-250 | Dry | 250 | 9.9 | 320 | 320 | 12.6 | 12.6 | 660 | 26.0 | 10.00 | 0.39″ |

| Product | Calcium Hydroxide | Tank Volume | Feeding Pump Suggestion | ||

| gram | L | US Gal | LPH | Gph | |

| KS-100 | 90-120 | 300-500 | 80-132 | 100-200 | 26-53 |

| KS-150 | 120-150 | 500-800 | 132-211 | 100-200 | 26-53 |

| KS-250 | 150-180 | 800-1200 | 211-317 | 200-300 | 53-80 |

Explosion Chart for KS-100

Explosion Chart for KS-150

Explosion Chart for KS-250